The UKF.01 design utilizes the latest in flow forming technology, offering not only a lighter but structurally stronger luxurious aluminium wheel. Available in 4 stunning finishes in 20 and 22″ staggered fitments.

- Split 5 Spoke Design

- Aluminium Center Cap

- 1-Piece Monoblock

- TPMS Compatible

- Manufactured With Flow Forming Technology

UNIKA FLOW FORMING PROCESS

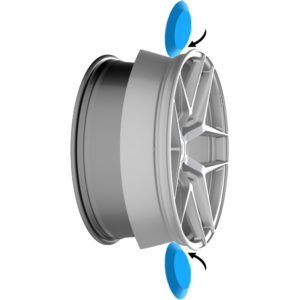

STAGE 1

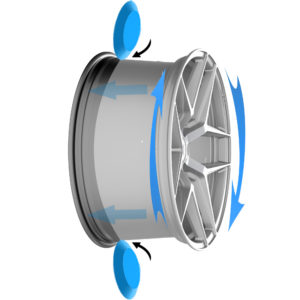

STAGE 2

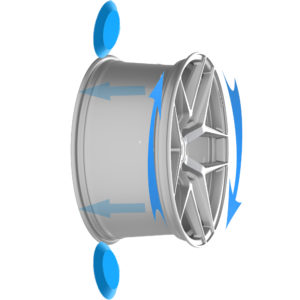

STAGE 3

After the raw casting has gone through the initial heat treatment process, the wheel is placed onto a heated flow forming drum which determines the final shape and size of the barrel.

The wheel is spun at high speed with extreme heat, while hydraulic rollers apply pressure to the barrel, stretching the alloy and forming its final shape and length as required.

Once the hydraulic rollers have reached the end, the flow forming process has been completed. The result is a condensed micro structure offering a lighter, stronger, high quality wheel.

Once the flow forming process has been completed, the wheel now moves on to the next stages of manufacturing. This includes CNC machining, submerged pressure testing, x-ray, run out, and balance testing, powder coating, paint and packaging. All UNIKA® Wheels are designed with the latest FEA analysis software to ensure a structurally sound, safe and high quality alloy wheel.